Oracle Fusion

Industry: Manufacturing & Trading

6 August, 2025Established in 1975, Al Hassan Group is a dynamic enterprise catering to modern industrial and infrastructure needs. With its LLC operations under the Manufacturing & Trading Strategic Business Unit (SBU), Al Hassan has emerged as one of the leading business groups in Oman. The company is actively involved in the manufacturing of low and high-voltage switchgear panels and the trading of electromechanical items.

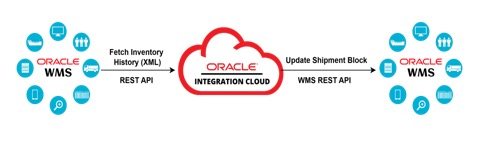

Al Hassan initially operated Oracle Fusion ERP integrated with a third-party WMS system. As part of a digital transformation initiative, they migrated to Oracle Fusion WMS Cloud. With this migration, they implemented Out-of-the-Box (OOTB) integrations provided by Oracle Integration Cloud (OIC). To enhance and tailor these integrations to meet specific business needs, they engaged 4i as their implementation and customization partner.

Customization of Out-of-the-Box (OOTB) OIC Integrations between Oracle Fusion ERP and Oracle Fusion WMS

Introduction

In today’s rapidly evolving digital ecosystem, pre-built or Out-of-the-Box (OOTB) integrations often fall short in addressing complex and changing business needs. This case study highlights how Al Hassan Group, in collaboration with 4i, overcame such limitations by customizing OOTB Oracle Integration Cloud (OIC) integrations between Oracle Fusion ERP and Oracle Fusion WMS Cloud. The result: scalable, efficient, and business-aligned integration processes.

Business Challenges

-

- Limited Flexibility: OOTB integrations provided by Oracle were read-only with minimal room for extension or customization.

-

- Mismatch with Business Structures: Standard integration flows did not support Al Hassan’s multiple Business Units (BUs) and custom data requirements.

-

- Need for Warehouse-Specific Flows: The lack of WMS-specific business processes, such as item repacking and shipping blocks, created operational delays.

Solutions Provided

A. Customization of OOTB Integrations

-

- Extended Procurement and Order Management Integrations to support multiple BUs.

-

- Enhanced Data Mappings externally to align with Al Hassan’s internal business expectations.

-

- Added Conditional Logic to control integration routing based on business context.

B. Development of New Integrations

-

- Item Master Interface: Automatically sync items created or updated in Oracle Fusion ERP to Oracle Fusion WMS.

-

- Repack Integration (Loop Back): Custom integration within WMS to transition item status from “picked” to “packed”.

-

- Shipping Block Interface (Loop Back): Prevent the processing of outdated sales orders by creating blocks in WMS.

Key Use Cases

Use Case 1: Real-Time Item Creation in WMS

-

- Scenario: When a new item is created in Oracle Fusion ERP, it should be immediately available in Oracle WMS Cloud.

-

- Solution: A custom OIC integration was developed using App-Driven Orchestration to trigger item creation in WMS in real-time.

-

- Benefit: Reduced delays and ensured consistency between ERP and warehouse operations.

Use Case 2: Repack Integration within WMS (Loop Back)

-

- Scenario: Warehouse users needed a way to transition items from “Picked” to “Packed” to track order fulfillment stages.

-

- Solution: A loopback integration was built within WMS that triggers based on user action, updating the item status.

-

- Benefit: Improved visibility into order fulfillment and faster warehouse operations.

Use Case 3: Shipping Block for Old Orders

-

- Scenario: Outdated or incorrect sales orders were being accidentally pushed to WMS, causing confusion and delays.

-

- Solution: A new integration was created to automatically block outdated sales orders from being processed in WMS.

-

- Benefit: Reduced fulfillment errors and prevented inventory misallocation.

Use Case 4: BU-Based Routing in Procurement Integrations

-

- Scenario: Al Hassan has multiple business units, and the OOTB flow didn’t support differentiated routing.

-

- Solution: Custom routing logic based on Business Unit ID was added to OIC integrations.

-

- Benefit: Enabled precise processing logic tailored for each BU, avoiding duplication and errors.

Tools and Technologies Used

-

- Oracle Fusion ERP (Procurement, Inventory, Order Management modules)

-

- Oracle Fusion WMS Cloud

-

- Oracle Integration Cloud (OIC)

-

- Business Intelligence Publisher (BIP) for custom reports.

Benefits Achieved

-

- Operational Efficiency: Faster and real-time synchronization of item and order data between ERP and WMS.

-

- Error Reduction: Automated data flows reduced manual entry and associated errors.

-

- Enhanced Flexibility: Ability to accommodate multiple BUs and evolving business rules.

-

- Improved Inventory Management: Loop back integrations streamlined WMS operations, especially repacking and blocking outdated orders.

Implementation Challenges

-

- Navigating the limited extensibility of OOTB flows.

-

- Bridging communication between ERP and WMS stakeholders.

-

- Handling environment setup and patching delays.

Summary

This case study demonstrates how Al Hassan Group achieved end-to-end automation of their inventory and order processes by extending and customizing Oracle-provided OOTB integrations using Oracle Integration Cloud. Through a mix of tailored development and strategic planning, they successfully transitioned to a more scalable, efficient, and integrated ERP-WMS landscape.